InfoSight Corporation has developed a technology for direct laser marking of automotive components with high contrast bar codes and text messages. The breakthrough traceability technology now allows for automatic identification of precision castings and forgings in harsh environments using standard bar code scanners without the need for unreliable adhesive labels.

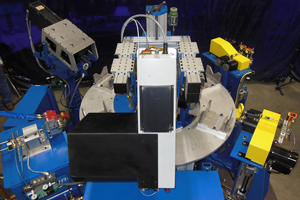

One such system has been designed and installed for major manufacturers of automotive steel forgings. For this application, the part is automatically loaded into the custom-designed marking cell and then radially oriented. Once the part is in position, the machine applies a uniform layer of proprietary laser-marking ink to cover the rough shot blast surface of the forging. Induction generated heat is then applied to allow the ink to cure, and a 10W CO2 laser and custom optics blacken the ink. After marking of text and barcoded information is complete, a barcode scanner automatically reads the message to verify the quality of the mark and then the part is indexed to an unload station. Typically a 6-station index table is used to allow for concurrent operations generating 15 second part-to-part throughput rates.

The resulting high contrast (black-on-white) text and barcodes are crisp, sharp images for maximum visibility and are highly resistant to various machining and cutting fluids. Other ink formulations have been developed for surfaces such as ceramics and aluminum, and to survive reheat furnaces. The finished component can be scanned with standard, inexpensive commercially available barcode scanners throughout the assembly plant to provide complete birth history data.

The resulting high contrast (black-on-white) text and barcodes are crisp, sharp images for maximum visibility and are highly resistant to various machining and cutting fluids. Other ink formulations have been developed for surfaces such as ceramics and aluminum, and to survive reheat furnaces. The finished component can be scanned with standard, inexpensive commercially available barcode scanners throughout the assembly plant to provide complete birth history data.

Specifications are subject to change without notice.

LabeLase is a registered trademark of InfoSight Corporation