Custom Automation

InfoSight designs & builds customized automated marking machines that can be integrated with robots to:

- Provide faster cycle times with a smaller footprint in the customer’s plant.

- Operate at temperatures from ambient to approximately 2000oF (1090oC).

- Utilize InfoSight marking software, PLC control software, and the Robot software to create a marking system that integrates seamlessly into the customer’s process.

- Marking technologies available include InfoDent® 8400 Stamping Systems, LabeLase® Direct Laser Marking, Automated Taggers, and Spray Marking Systems.

Check out this demo video from 2021 AISTech.

The InfoSight model KE2900 Automatic Single Station Slab Tagging System for stationary slabs is the ideal barcode tag solution for MIG-welded tag identification of hot carbon steel slabs with high-contrast marking.

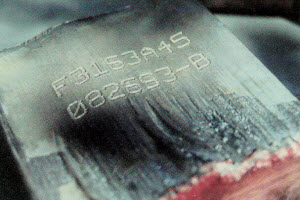

The ID8400 model InfoDent® marking system is a programmable heavy duty system that was designed specifically for hot or cold marking applications in the steel industry where reliable operation under severe conditions is an absolute requirement.

The Single Bar Stamping System is an industrial identification stamping system that utilizes the InfoDent® ID8400 stamping head and is designed to quickly and permanently stamp variable message data onto the ends of hot or cold steel billets, blooms, rounds and beam blanks.

Many mills throughout the world are turning to automated equipment to do their identification. Until now, there has been no reliable system to automatically print and apply high quality bar coded tags to hot slabs, thereby reducing man-hours.

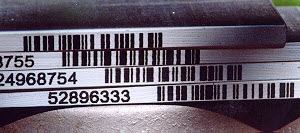

InfoSight's Model 2951 FlagTag™ Metal Tag Marker and Applicator uses a moving, focused CO2 laser beam to darken the pre-coated (white) tag surface to produce high definition black characters, bar codes, or even logos. The text and bar code data is downloaded from the host computer or entered from an operator terminal. The resultant tag is then automatically sheared and mig welded to slabs, billets or blooms.

InfoSight Corporation has developed new technology for direct laser marking of automotive components with high contrast bar codes and text messages.

In as low as 6 seconds, the plate edge is referenced and labeled with a mark that is suitable for manual or automatic identification of stacked plates.

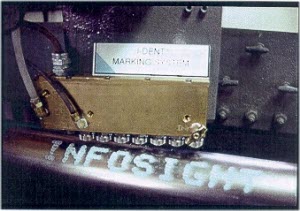

The I-Dent® Spray Marking System from InfoSight Corporation offers a practical and cost effective alternative to manually stenciling products in an industrial environment.

The I-Dent® Marking System utilizes a non-contact multi-nozzle Printhead which is capable of producing a full range of upper case alphanumeric characters 3/4 to 6 inches high.

Page 1 of 2