LDAR and The Clean Air Act

The Clean Air Act of 1963 (CAA) is a United States federal law designed to control air pollution on a national level. It is administered by the U.S. Environmental Protection Agency (EPA), in coordination with state, local, and tribal governments.

The CAA mandates implementation of Leak Detection and Repair (LDAR) programs in facilities that produce volatile organic compounds. LDAR technicians are required to monitor and audit each facility's fugitive emissions (leaks). The EPA has issued a list of best practices that include tagging each point in the process where leaks could occur. LDAR components include:

- Valves

- Pumps

- Compressors

- Flanges

- Connectors

- Pressure Relief Devices

When the EPA published its 2015 accomplishments the list included:

- $4 Billion in court-ordered environmental projects resulting from criminal prosecutions;

- $404 Million in combined federal administrative, civil judicial penalties and criminal fines; and

- 129 combined years of incarceration for sentenced defendants.

Obviously, no company can afford to ignore the EPA’s LDAR mandates.

To simplify and reduce the cost of LDAR compliance, InfoSight Corporation offers solutions for onsite / on-demand printing. Our combination of nearly indestructible stainless steel tags and industrial-grade printers reduces the recurring cost of tags, simplifies retagging, and can reduce the burden of some record keeping tasks.

Customers pay less for our tags and are secure in the fact that our tags will last for the lifetime of the component. Plus, they no longer need to wait for the delivery of preprinted tags. (See LDAR Applications Brochure for more information.)

InfoSight’s special LDAR package includes our proven LL1000 printer, a custom tag winder that allows unattended and overnight printing, and our innovative LDAR tags that survive heavy weather, salt-water environments, dilute acids, and many organic cleaners.

- The LL1000 includes design and communication software that allows on-the-fly customized printing and integration with many database programs. The software also provides serialized printing and self-generating bar codes for automated component identification.

- The tag winder integrates easily with the LL1000. It allows batch printing of more than 1000 tags, rolling them up in a neat coil.

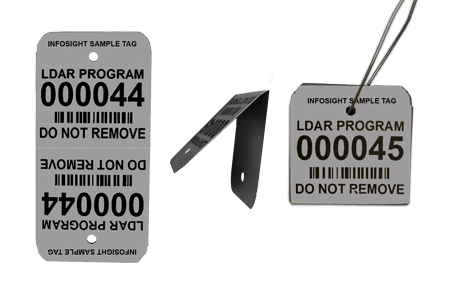

- The system also includes durable stainless steel tags in a special LDAR format. The unique design provides identification data on both sides of tag. Tags are available in a variety of colors to make it easy for field testers to find components with set test cycles or tagged for repair.

- Technical service is always available and included in the price of the printer.

For more information see our LDAR Applications Brochure.

Who is benefiting from utilizing InfoSight’s LDAR solution?

LDAR mandated include industries that provide or produce:

- Petroleum (Refineries)

- Gasoline Distribution

- Onshore Natural Gas

- Chemicals and Transfer Operations for plastics production

- Pharmaceuticals

- Pesticide Active Ingredients

- Pulp and Paper

- Hazardous Waste

- Municipal Solid Waste Landfills

- Marine Unloading

- Magnetic Tape Manufacturing

- Aerospace Manufacturing and Rework

- Site Remediation (for all industries shown above)

InfoSight’s special LDAR package allows your company to meet changing requirements or include specific information required by State, Canadian or European regulations as well as U.S. EPA mandates. However, InfoSight’s printers, tags and accessories are available in many combinations and capable of solving asset identification problems for maintenance departments as well as LDAR groups.

For more information about InfoSight’s solutions for LDAR programs, Contact Us to arrange for a conversation with one of our technical specialists. Or, for an immediate response, call us at +1 (740) 642-3600.

Specifications are subject to change without notice.