Automatic or Manual Welding Attachment

|

|

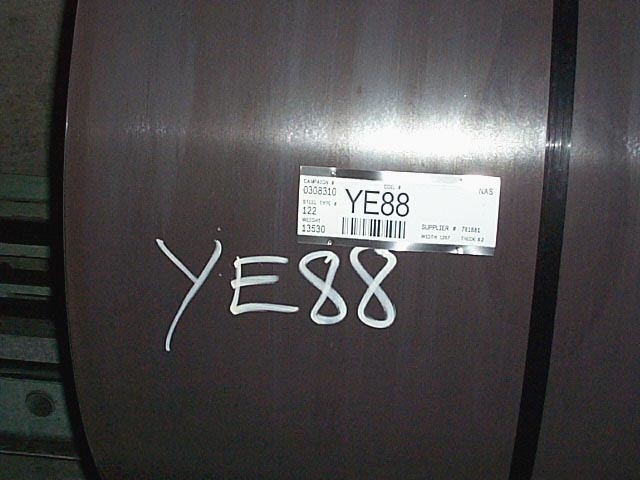

These tags are attached to a wide variety of products. They help prevent mixed batches and lost product with easy to read, unique piece-marks, location identifiers, bar codes and other must-have identifiers. This unique InfoTag® metal tag is bare-edged allowing the tags to be welded to the product.

Utilize welding methods to attach tags to steel for permanence. Download the PDF version of this product page. Technical specifications are subject to change without notice.

|

| InfoTag® Specifications | |

|---|---|

| Industry | Industrial manufacturing, distribution |

| Typical Customer | Harsh environments: more durable than paper or plastic |

| Purpose | Rugged barcode-ready identification - will not tear or detach during handling, processing and shipping |

| Resistance | Heat: 1800°F (1000°C) to cool down Chemical: Resistant to common solvents Abrasion: Moderate Ultraviolet: Highly resistant to sunlight and fading |

| Sizes | Width: 3 in. (76 mm) and 4 in. (101mm) Length: to customer specifications not less than 1 in. (25 mm) |

| Typical Size | 4 in. X 10 in. (101 mm X 254 mm) |

| Composition | Metal with high contrast laser-markable coatings |

| Available Forms | Print on-site with one of InfoSight’s durable, laser metal tag printers or pre-printed by InfoSight |

| Available Colors | Standard white - colors available |