By Edward O'Neal

Until recently, wire rod coil manufacturers have been in a Catch-22 situation when it came to attaching identification to the coils of wire they produced.

Plastic and paper tags had the potential to make the inventory process easier with their ability to hold bar-coded information, virtually eliminating human error as a factor. These tags were able to survive the process of pickling – immersion in heated baths of hydrochloric or Sulfuric acid for periods of up to 90 minutes at a time.

However, when it came to the process of annealing – baking the wire at temperatures of 1400oF or greater for extended periods of time – these tags would vanish in a puff of smoke. Applying tags after the annealing process meant a wait of several days until the coils cooled to a more tag-friendly temperature. This opened the door to more potential for human error.

However, when it came to the process of annealing – baking the wire at temperatures of 1400oF or greater for extended periods of time – these tags would vanish in a puff of smoke. Applying tags after the annealing process meant a wait of several days until the coils cooled to a more tag-friendly temperature. This opened the door to more potential for human error.

Metal tags breezed through the annealing process, but in some cases would not survive pickling. Bar-coding systems for metal tags were not suitable for all industrial applications. This meant the use of manual inventory control, which again meant the risk of human error. Further, the machines to stamp the dog tags were noisy and the upkeep was high.

This was the state of the industry in 1998, when Ontario’s Ivaco Rolling Mill – one of the world’s largest producers of wire – approached InfoSight in Chillicothe, Ohio. “At the time we needed more than the existing tag technology offered,” said Yves Levac, Ivaco’s Operations Supervisor. “We had an old embossing machine we used to manually punch out metal tags for the rolls. We would put what information we could on them and produce the tags by order. It was time consuming and expensive, and if there was a change in the schedule, the new tags were useless. With laser scanning technology everywhere you looked, we knew there had to be a way to develop a better system.”

Research on the subject led Ivaco to InfoSight. “We had seen their ads in trade journals and visited their web site, and we knew about their work,” Levac said. “So we contacted them, and they actually welcomed the challenge of creating a product to meet our needs.”

As a designer of custom identification solutions for the metals industry, InfoSight created the first touch-free, laser-markable tag system in 1995. Now Ivaco wanted to use that technology for an automated inventory system.

According to Levac, of primary importance was the tag’s ability to carry lots of information. “After they’re produced, the coils go into inventory in the yard. We wanted to use wireless scanning technology to check those coils for quality assurance approval, and to make sure they went to the right customer. Bar-coding would give us that and other information, like which client the batch was for, the diameter of the wire and the heat number. Scanning would put all of that information at our fingertips.” In addition, the tag needed the ability to survive the harsh processes of pickling and annealing – not just by the manufacturer, but by the customers as well. As Ivaco described it, the ideal tag would be attached to the wire bundle once and would not have to be removed for any part of the downstream process. Such a tag would give Ivaco cradle-to-grave tracking with superior inventory control to insure clients of a quality product. Ivaco needed a system that could deliver one tag every 11 seconds. “Because of the nature of the business, it was important to have tags delivered to us in realtime,” Levac said.

Soon after InfoSight began work on the project, complications developed. Tests of tag formulations showed it could withstand the pickling and annealing process, only to fail when reprocessed by Ivaco’s customers. It turned out that each of Ivaco’s customers had their own set of specifications in regard to processing times, acid concentrations and baking times. This required feedback from each client. “It took three to six months of research and development and working with InfoSight to get the tags right,” Levac explained. “They would make test tags for us. We would run them through our process, then send them to our clients and have them send them through their processes. Then we would gather up the test results and meet with InfoSight to discuss what worked, what hadn’t and why.”

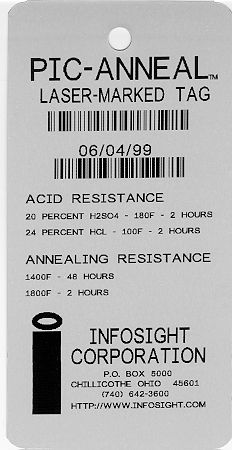

At the end of this time, InfoSight developed a tag that met Ivaco’s needs – and would withstand the rigors put upon it by the processes of their different customers. Their PIC-ANNEAL® tag has a two-hour resistance to acid baths of 20% H2SO4 at 180o F and 24% HCL at 100o F. It also withstands 1400o F heat for 48 hours and 1800o F for 2 hours.

At the end of this time, InfoSight developed a tag that met Ivaco’s needs – and would withstand the rigors put upon it by the processes of their different customers. Their PIC-ANNEAL® tag has a two-hour resistance to acid baths of 20% H2SO4 at 180o F and 24% HCL at 100o F. It also withstands 1400o F heat for 48 hours and 1800o F for 2 hours.

The PIC-ANNEAL® Laser-Marked tags measure 3” by 6” and sport a hole punched near the top for easy attaching to wire coils. The tags are marked with a standard CO2 laser, resulting in black print across the light gray surface. The bar codes printed on the tags are readable by any standard bar code reader.

“In the end,” Levac said, “InfoSight created the tag that we needed. And I’m happy to say that their service hasn’t stopped there. If we need something, all we have to do is call our local representative, EXA; their Product Manager, Ed O’Neal; or Quality Assurance. They’re always there to advise us and give support to what they produce.”

In addition to this project, InfoSight tackled a number of other challenges, including the development of a tag that could survive the impact of a fork truck. Such challenges are what they thrive on as the nation’s premiere creator of fully developed custom identification solutions, including tags, printers and the machines to apply the tags.

As Ed O’Neal, InfoSight’s Laser Product Manager, says, “If someone has a tagging need that can be solved with a slip of paper, turn them away. We want the tough stuff… the kind of jobs that make other companies cringe… the kinds of jobs that other companies cannot do. This is what we have built our business and our reputation on."

PIC-ANNEAL® is registered trademark of InfoSight Corporation

Download the PDF whitepaper.