Fully Automated System for Applying Protective Coating to a Tire's Raised White Letters or White Sidewall area.

AUTOMATED SIDEWALL COATING SYSTEM

INFOSIGHT CORPORATION has designed and installed computer controlled, non-contact, spray coating systems for the tire industry, which require no operator intervention. These highly sophisticated, but user-friendly, systems have solved the problems that have plagued the tire industry for years. It will no longer be necessary for coating material to cover the entire sidewall but only the white area. There will not be any uneven coating thickness or wasted coating material.

SYSTEM DESCRIPTION

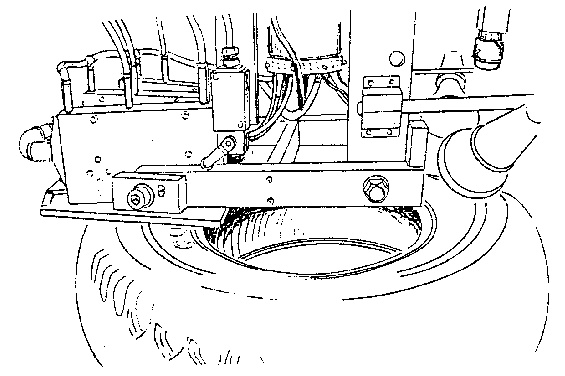

The INFOSIGHT Sidewall Coating System is a microprocessor based system that sprays coating material only on the white areas of the sidewall. The older version uses a CCD camera to detect the white areas, then signals the appropriate spray nozzles to activate, applying a uniform coating over the whitewall area, only. A newer version, offered in 2004, uses a bank of high speed white sensors to detect the white areas and mark a spinning tire.

SYSTEM COMPONENTS

The system consists of an electronics enclosure to supply power and to process all input and output functions, a cleanup enclo-sure to permit purging and cleanup of the spray nozzles, a coating pump for charging the spray nozzles, a rotating mecha-nism including drive, gearbox, encoder, white sensors, nozzles as required, and a tire lifting/centering conveyor. The lifting/ centering conveyor receives a tire, centers and raises it to a fixed elevation beneath the coating nozzles, and signals the coating system to begin spraying. At the end of the sequence (about eight seconds), the lifting/centering conveyor lowers the tire and transports it out of the coating station to the customer's conveyor. The new system is capable of processing a random assortment of tires having a bead diameter range from 13" to 19".

SYSTEM COMPONENTS |

Electronics Enclosure, Clean up Enclosure, Coating Pump, Rotating Mechanism, Lifting/Centering Conveyor |

PRODUCT TO BE MARKED |

White Sidewall or RWL (raised white letters) tires |

MATERIAL |

Rubber |

PRODUCT TEMPERATURE |

Ambient or hot |

STRIPE WIDTH |

Variable, automatically adjustable |

OVER SPRAY |

Typical 0.5" above and below the white, and 1" before and after the white |

CYCLE TIME |

8 seconds tire-to-tire typical |

UTILITIES REQUIRED |

Electrical 480 VAC. 3 phase 60 Hz., Air 75 PSI at 23 scfm |

Scope of Work (InfoSight) |

Supply Sidewall Coating system, installation and start-up assistance at standard field service rates. |

Scope of Work (Customer) |

Furnish all labor, tools, equipment necessary to completely install InfoSight furnished equipment onto the customer's conveyor, including all interconnecting piping and wiring from cutoff point on machine. |

Specifications are subject to change without notice.