InfoSight manufactures custom machinery for industrial applications that integrates our advanced marking, tagging and barcode reading products to solve difficult manual and automatic identification applications worldwide.

InfoSight's main production facility has office space for engineering and management staff, a complete machine shop, assembly and integration/test floor, paint booth, inventory stores and a shipping/receiving dock. Our engineering staff includes mechanical, electrical and software designers with many decades of combined experience designing custom machinery for industry.

Examples

The following are examples of some of the custom machines we have recently designed and manufactured.

Robotic Automation for Marking Systems

InfoSight designs & builds customized automated marking machines that can be integrated with robots to:

InfoSight designs & builds customized automated marking machines that can be integrated with robots to:

- Provide faster cycle times with a smaller footprint in the customer’s plant.

- Operate at temperatures from ambient to approximately 2000oF (1090oC).

- Utilize InfoSight marking software, PLC control software, and the Robot software to create a marking system that integrates seamlessly into the customer’s process.

- Marking technologies available include InfoDent® 8400 Stamping Systems, LabeLase® Direct Laser Marking, Automated Taggers, and Spray Marking Systems.

Portable Catalytic Converter Laser Marking Machine

This portable machine was designed to mark a barcode and man-readable text on catalytic converter cores. The cores are manually loaded at the left, stamped with a special white coating, which is then heat dried and cured and then laser marked. Finally the parts are manually unloaded on the right. A touch-screen interface provides complete operator interface and control of the machine.

This portable machine was designed to mark a barcode and man-readable text on catalytic converter cores. The cores are manually loaded at the left, stamped with a special white coating, which is then heat dried and cured and then laser marked. Finally the parts are manually unloaded on the right. A touch-screen interface provides complete operator interface and control of the machine.

Coil Tagging Machine - Prints and Applies on demand Stainless Steel Tags

This custom coil tagging machine prints on-demand Stainless Steel tags (straight or folded) with barcode and man-readable text. The machine will position itself to downloaded vertical height and traverse horizontally to spot-weld the tag at the centerline of the coil. Coil temperatures range from ambient to 1800° F. This system has very low maintenance and high reliability compared to traditional ink identification systems.

This custom coil tagging machine prints on-demand Stainless Steel tags (straight or folded) with barcode and man-readable text. The machine will position itself to downloaded vertical height and traverse horizontally to spot-weld the tag at the centerline of the coil. Coil temperatures range from ambient to 1800° F. This system has very low maintenance and high reliability compared to traditional ink identification systems.

Slab Tagging Machine - Prints and Applies on demand Stainless Steel Tags

This custom slab tagging machine prints on-demand Stainless Steel tags with barcode and man-readable text. After printing, the tag is transferred to a MIG welder/applicator where it is welded to the slab. Slab temperatures range from ambient to 1800° F. This system is very cost effective compared to traditional nail-on systems.

This custom slab tagging machine prints on-demand Stainless Steel tags with barcode and man-readable text. After printing, the tag is transferred to a MIG welder/applicator where it is welded to the slab. Slab temperatures range from ambient to 1800° F. This system is very cost effective compared to traditional nail-on systems.

Billet Stamper Prints On-Demand Text Using the InfoDent® Impact Stamper

This custom stamping machine uses the InfoSight InfoDent® marker to create text on ambient to 1800° F billets for permanent identification. Can mark low stress dot matrix characters to solid line (fully formed) characters.

This custom stamping machine uses the InfoSight InfoDent® marker to create text on ambient to 1800° F billets for permanent identification. Can mark low stress dot matrix characters to solid line (fully formed) characters.

Billet Stamper Prints Multiple Strands

This custom stamping machine uses the InfoSight InfoDent® marker to mark multiple strands simultaneously. Data can be received and stored for each strand and when a particular strand reaches the marking location the stamper will move to that location, press against the billet and mark the message. A six strand machine is shown that uses two stampers to simultaneously mark two strands. Each stamper handles three strands. Other arrangements are available.

This custom stamping machine uses the InfoSight InfoDent® marker to mark multiple strands simultaneously. Data can be received and stored for each strand and when a particular strand reaches the marking location the stamper will move to that location, press against the billet and mark the message. A six strand machine is shown that uses two stampers to simultaneously mark two strands. Each stamper handles three strands. Other arrangements are available.

Dual Coil Marker Prints Text on Steel Coils

This custom dual coil marker uses two of the InfoSight X-Y Continuous Character Ink Markers to mark a hot coil at the 10 O'clock and 2 O'clock positions. The water based ink can mark coils from 400° F to 1600° F. The continuous characters are highly readable for crane and fork truck operators.

This custom dual coil marker uses two of the InfoSight X-Y Continuous Character Ink Markers to mark a hot coil at the 10 O'clock and 2 O'clock positions. The water based ink can mark coils from 400° F to 1600° F. The continuous characters are highly readable for crane and fork truck operators.

Axle Marker

This custom marker uses the patented InfoSight LabeLase® technology to identify axles with man readable characters and machine readable barcodes. It is designed to be installed in a totally automatic processing line.

This custom marker uses the patented InfoSight LabeLase® technology to identify axles with man readable characters and machine readable barcodes. It is designed to be installed in a totally automatic processing line.

Crane-mounted OptiCode System with Joystick Control

This custom machine integrates an OptiCode barcode reader onto an industrial crane for locating product in a storage yard or production area. A joystick gives the crane operator complete control over the reader's camera for pan, tilt, zoom and focus, while a CRT monitor provides visual feedback. The reader can interface with the plant's information system to provide tracking feedback.

This custom machine integrates an OptiCode barcode reader onto an industrial crane for locating product in a storage yard or production area. A joystick gives the crane operator complete control over the reader's camera for pan, tilt, zoom and focus, while a CRT monitor provides visual feedback. The reader can interface with the plant's information system to provide tracking feedback.

Capabilities

Machining

- Turning

- Milling

- CNC Milling

- Drilling

- Surface Grinding

Mechanical Fabrication and Assembly

- Welding (ARC, TIG & MIG)

- Shearing

- Painting

- Assembly of mechanical mechanisms from small parts and sub-assemblies to large complex machines.

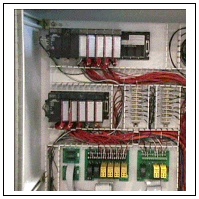

Electrical Fabrication and Assembly

- Complete electrical fabrication and assembly capabilities from small electrical panels to complete electrical enclosures.

InfoSight® Mechanical Engineering and Design

- Complete mechanical design capabilities using AutoCAD from small mechanical devices to large complete machines.

- Hydraulic design capability.

- Pneumatic design capability

InfoSight® Electrical and Software Engineering and Design

- Complete electrical engineering capabilities from power distribution to machine control.

- PLC programming using AB, Siemens, GE Automation Direct and others.

- Complete electronic board design capabilities including custom software.

- Software design capabilities to fit your needs