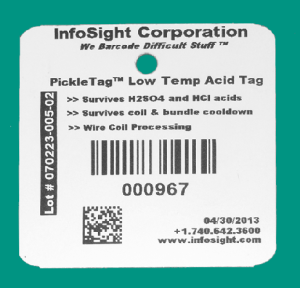

PickleTagTM is intended for applications in the metal rod and wire processing industry. It is resistant to heat, chemical, and environmental exposure present in metal rod and wiring processing.

Features

- Barcodes and text are readable after hot acid baths.

- Reduced handling for greater productivity and worker safety.

- Readable text and barcodes before and after pickling.

- Design tags to include alphanumeric characters, 1D and 2D barcodes, and logos & graphics with the user friendly LabeLase® ProducerTM Software.

- Print on InfoSight LabeLase® Printers.

- Pre-printed tags are available.

- Various tag attachment techniques are available.

Download the PickleTag™ brochure here

Specifications

|

Industry |

Metal rod and wire processing |

|

Typical Customer |

Rod mills; Wire mills: Wire processing plants; Fabricators; Anodizers; Metals service providers |

|

Purpose |

Tracking finished and unfinished work pieces through a metal pickling process |

|

Resistance |

Heat: 1000°F (538°C) for 2 hours |

|

|

Chemical: 180°F (82°C) in 20 H2SO4 for 2 hours; 100°F (38°C) in 24% HCL for 2 hours |

|

|

Abrasion: Moderate |

|

|

Ultraviolet: Highly resistant to sunlight and fading |

|

Sizes |

Width: 3.0 in (76 mm) Lengths: to customer specification, not less than 1.0 in (25 mm) Typical Lengths: 3.0 in (76mm), 4.0 in (102mm), 5.0 in (127mm) |

|

Composition |

Metal with high contrast laser-markable coatings |

|

Available Forms |

Print on-site with one of InfoSight’s durable, laser metal tag printers or pre-printed by InfoSight |

|

Available Colors |

Standard white, colors by special order |

Technical specifications subject to change.

PickleTag and Producer are trademarks of InfoSight.

LabeLase is a registered trademark of InfoSight.